What is Aluminum Sheet Metal?

Simply defined, aluminum sheet metal is a product formed when aluminum material is pressed and rolled under intense pressure. Generally, the aluminum sheets are lightweight but strong enough to be used for a wide range of applications.

The extreme versatility of the aluminum plates is boosted by the ease of installation and maintenance. This explains why the aluminum sheet is among the most popular metal sheets.

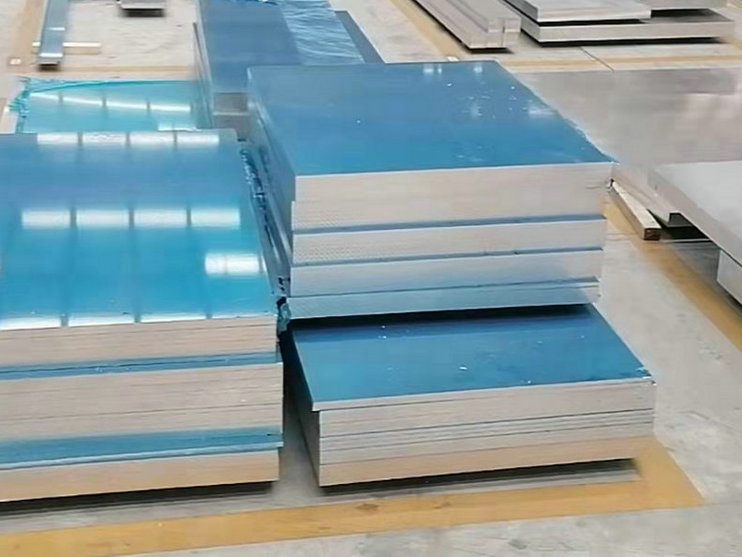

Different types of coatings are applied to the aluminum sheet metal. The purpose of coatings is to increase the strength and durability of the aluminum sheets. They also make the sheet applicable to different conditions.

There are different surface finishes of the aluminum metal sheet. Some a/re smooth and uniformed while others are rough or rugged. The choice of the aluminum plate texture will depend on its application areas.

Aluminum sheet metal comes in different sizes. You are free to choose the size that will perfectly fit your application. All you need is to communicate with the aluminum sheet metal manufacturer and specify the size. As expected, the price will depend on the size of the aluminum metal plate

Types of Aluminum Sheet Metal

Aluminum sheet metals are not all the same. They come in different forms. Here are the types of aluminum sheet metals that you will find in the market.

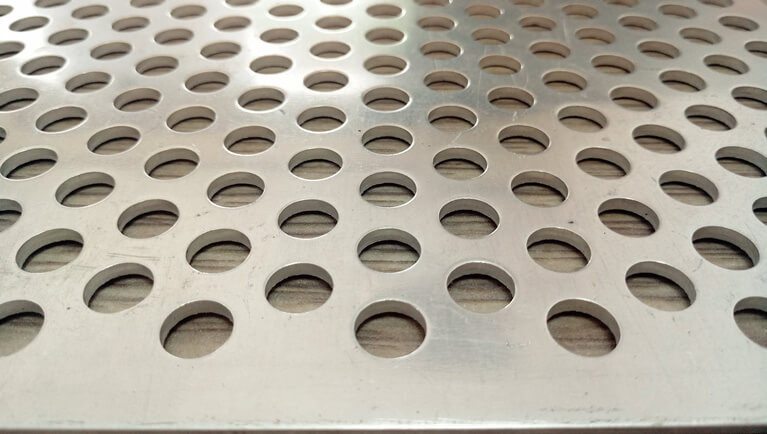

1. Perforated aluminum sheets

Also known as the plate aluminum, it is oftenly used in applications where there is a need to add aesthetic value. They are known for their good looks. Such applications include interior/exterior design, construction of ceilings, sun shades, screens among other decorative panels for building, construction and architecture.

This type of aluminum sheet is also used in food, pharmaceutical, and laboratory industries.

2. Chequered aluminum sheets

As the name suggests, this type of aluminum sheet is characterized by numerous raised hatch marks on one side and the other side remains untextured marks. Some people call these aluminum sheets to tread plates durbar floor plates and bar sheets.

These aluminum sheets are sturdy and can withstand high-impact force. They are perfectly suited for both interior and exterior applications. Because of their strength and sturdiness, you can use them for heavy-duty applications. These include loading bays, car parks, flooring systems service corridors among others.

3. Brushed aluminum sheets

Almost all the aluminum sheet metal exists in two forms. They are either brushed or unbrushed. In this context, we are using brushed to mean that the metal sheet ha a fairly uniform pattern. Alternatively, some have light scratches and scuffs that are uniform and parallel to each other.

This type of aluminum sheet metal is also ideal for creating aesthetic effects. They are stylish and well-polished. You can use them to accentuate your interior design ideas. They are applicable to both domestic and industrial applications.

4. Composite aluminum sheet

This type of aluminum sheet is usually abbreviated as ACS. It comprises pieces of coil-coated aluminum that are bonded to the non-aluminum core which in most cases in plastic. They are among the lightest aluminum sheets metal in the market.

Composite aluminum sheets are also robust since they carry minimal weight. This feature makes them an ideal choice for external cladding. Because of this, they are sometimes known as dibond sheets or sandwich panels.

Their lightweight also makes it easy to install and maintain. They can be easily cut and shaped for different applications. Some of their applications include cladding and decorations

5. Anodised Aluminium Sheets

In chemistry anodising is a process of introducing a layer of oxygen onto the metal sheet hence increasing its thickness. This means that anodised aluminum sheets have an oxygen layer. The goal of this layer is to increase the resistance of the metal from the effects of wear and tear. It can also be used for increasing the adhesiveness of the metal, especially hen you want to attach other chemicals such as glue and paints onto it.

Anodised aluminum sheet metals are commonly used for decorations. This is because they tend to create strong bonds with other materials.

So, which type of aluminum sheet metal will perfectly work for your application? Once you identify it, go ahead and make the purchase. If not sure, then consult experts from the best aluminum sheet metal manufacturers.

Related Comments